We care about your valuable engine and equipment. So, you can put your concerns with engine and equipment failure to rest and focus on the important things in your life. We understand that efficient operation of your engine means your successful management of your business, and your well-being. Experts at TNZ have an immense focus on having products that meet the needs of customers.

Finding Equivalent Lubricant

In choosing a suitable lubricant, industrial lubricants in particular, a number of factors must be taken into account. The manufacturer’s recommendation is a great starting point, however not sufficient. The majority of manuals are written for ideal conditions and not based on the actual environment of the equipment. Equipment manuals introduce some reputable lubricant brands. Here, you can find their equivalent to TNZ products.

Engine oil finder

Choosing a suitable oil to ensure proper maintenance and performance of the engine is one of the most significant concerns of car owners. They are well aware that the engine’s life, fuel consumption and emission of pollutants depend on viscosity, quality and performance level of the oil. The main reference in choosing the oil is the manufacturer’s guide. This section is gathered from various car manuals.

Maritime industries have witnessed immense developments over the recent years. A significant amount of concern is aimed at maritime equipment owners, with regards to the cost repairs and maintenance. They are well aware that having a high-performance lubricant can reduce many of such costs. TNZ understands the concern and, by producing a wide range of lubricants, assures its customers that it is aware of the importance of protecting maritime equipment. We provide suitable lubricant for any part of your equipment that incurs high costs due to the lack of a high-performance lubricant. Our technical advisors will also help you take better care of your strategic equipment by condition monitoring of under service oils to further protect them. With TNZ you can trust your lubricant.

Whether you are a fisherman, working on a commercial or coastal vessel, your profitability is heavily dependent on your ability to control costs of fuel, and maintenance of the equipment. Therefore, optimizing your engine’s performance can lead to a significant difference in your expenses. Using low quality oil may seriously decline engine performance, cause severe damage to your equipment as well as incurring extra charges. To ensure a successful maritime operation you need to manage costs. TNZ MARISEA-I PLUS optimizes your engine performance by reducing friction. In addition, this product reduces fuel consumption, maintenance costs and pollutant gas emissions Read more+

Ships mainly use heavy fuel, which is obtained as a by-product of the distillation of crude oil. Crude oil contains sulfur, which after combustion in the engine, is released along with the exhaust gases. Sulfur oxides (SOx) are harmful to human health. The existence of SOx in the atmosphere can lead to acid rain which in turn damages crops, forests, and aquatic species, and contribute to the acidification of the oceans. Limiting SOx emissions from ships improves air quality and protects the environment. International Maritime Organization (IMO) first implemented a regulatory framework to limit the emission of SOx in 2005 under the international convention for the prevention of pollution from Ships, known as the MARPOL convention. Over time, restrictions on the release of sulfur oxides have gradually become stricter. From January 1, 2020, the amount of sulfur in the fuel used on ships operating outside designated emission control areas will be reduced to 0.5 % wt. This significantly reduces the amount of sulfur oxides emitted by ships and has major health and environmental benefits for the world, especially for coasts and harbors.

Book-reading O'clock

We would like to share with you a number of articles and books that have helped us to increase our technical knowledge in the field of lubricants

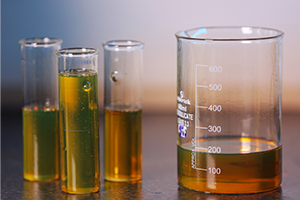

QC labratory

This is Tajhiz Niroo Zangan’s quality control laboratory. This unit’s responsibility starts as raw materials enter the factory and carries on until shipping orders to the customers. We are also responsible for monitoring production quality, additionally, obliged to approve of products with a quality exceeding national standards for packaging

Technical services

Close contact with the customers has enabled us to have a better understanding of their concerns regarding their equipment. Their trust allowed us to perform more in-depth analyses of their equipment and design a product with as quality as international standards

FAQ

Choosing a suitable oil to ensure proper maintenance and performance of the engine is one of the most significant concerns of car owners. They are well aware that the engine’s life, fuel consumption and emission of pollutants depend on viscosity, quality and performance level of the oil. The main reference in choosing the oil is the manufacturer’s guide. This section is gathered from various car manuals.

Are you looking to make your own lubricant?

You are in the right place, view our projects, enjoy them and contact us if you are interested

Industrial oils

Industrial equipment is expensive and of high value. We are well aware of the importance of their maintaining. We are also aware that this equipment is operated constantly so as to sustain healthy production. The importance of maintaining off-road machinery, heavy-duty diesel machines, gearboxes, compressors, turbines and your other valuable equipment is apparent to us. Choosing the right lubricant is a stepping stone to achieve higher performance and save costs. The industry is in constant demand for effective products. Re-evaluating the choosing process of lubricants is an easy yet professional way to reassure proper performance and maintenance of the equipment. If you are interested in choosing the best lubricant technology for a specific equipment, you can contact TNZ’s R&D.

Some of our projects

Exmoor-NH3 is a full-synthetic lubricant (PAO based) for refrigeration compressors. This product has been developed in close collaboration with customers and equipment manufacturers and is specifically designed to operate in ammonia refrigeration systems, which experience very high temperatures as well as temperatures below -45 °C. The very low pour point of this lubricant reduces the thickness of the lubrication film in the evaporator unit and results in excellent heat transfer. This product is highly stable, fully compatible with the system and resistant to sludge. The Exmoor-NH3 has a long service life, saving time and money. Cost savings are achieved through long oil change intervals and low filter failure rates. This wax-free lubricant can be used in both rotary and reciprocating compressors (pistons) that run on NH3 coolant, and the additives used in the formulation have been approved by the strict functional requirements of DIN 51506 (VBL, VCL, VDL). Exmoor-NH3 enables you to choose an oil with optimal performance through excellent device protection against wear, long-lasting oil and high system efficiency. It is used in the pharmaceutical industry, which requires low temperature control, and in large commercial operations, including refrigeration, marine systems, and the food industry. We are proud that a wide range of industries in Iran rely on TNZ compressor oil and benefit from a reliable lubrication performance.

We know that lorry drivers are skillful and passionate, and we also understand their hard and dangerous working conditions. Lorries are a vital part of economic growth, thus maintaining their equipment is of extreme importance in order to achieve commercial goals. By using TNZ oil, even in the harshest situations, you can rest assure of the best protection and highest performance. TNZ produces specialized oils for lorries, lift trucks, excavators and other on- and off-road equipment. Our products range from lubricants for modern engines to lubricants for older vehicles and equipment which are not able to withstand modern synthetic lubricants.

Protecting the gearbox and the inner components against wear and corrosion is crucial to prolonging the life of the device and preventing it from malfunctioning. Holstein-CLP series are special gear lubricants designed for lubrication of industrial gears operating under high-load carrying. Technology and innovation are combined to enable industrial and maritime equipment operators to choose an oil that delivers best possible performance by increasing protection against wear and damage. We at TNZ are well aware of the performance requirements of gear oils and the associated risks of using low quality products, and therefore recommend our customers to use quality products in addition to properly maintain their equipment to ensure optimum performance. Holstein-CLP gear oils are formulated with additives that exceed the stringent requirements of DIN 51517-Part 3. This set of lubricants is produced in the viscosity grades of 46, 68, 150, 220, 320, 460, 680 and 1000.

![Car [99.9.29]-01](http://tnzoil.com/wp-content/uploads/2020/12/Car-99.9.29-01.jpg)